First understand what is PVC. Polyvinyl-Chloride is known as PVC. It is easy to start PVC pipe manufacturing business in small as well medium scale. PVC pipes are widely used in electrical, irrigation and construction industries. PVC replaces many materials like wood, paper and metal in many applications. It is widely used as electrical conduits in domestic as well in industrial use.

PVC pipes are widely used for water supply as it has suitable characteristic for it. It is lightweight and has low cost. PVC pipes are easy to install and are non-corrosiveness. The PVC pipe has high tensile strength to bear the high fluid pressure. PVC pipes are high resistant to almost every chemical and have maximum heat and electrical insulation properties.

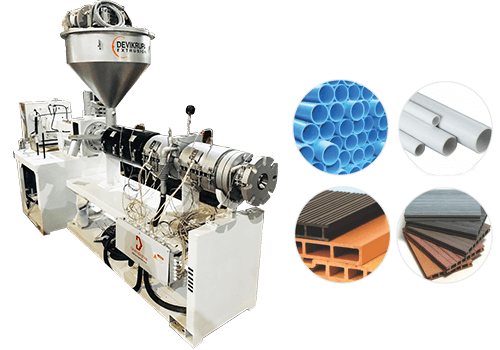

In India Devikrupa Group Manufactures wide range of PVC Pipe Making Machine.

Indian Market for PVC Pipe

The demand of the PVC pipe is increasing in India as the infrastructure is growing high. PVC pipes are widely used in construction and agriculture sector and the demand is rising in the nearest future. PVC pipes are widely used for various purposes like water supply, spray irrigation, deep tube well schemes and also for land drainage.

The slotted and corrugated pipes are mainly used for drainage of water from land where the waterlogging is necessary. The demand is increasing in the rural areas for water supplies, irrigation, with advancement in construction industry and with the extension of electricity network in rural areas. More than 60% of PVC pipe demand is in up to 110 mm outer diameter.

PVC Pipe Machine step by step Manufacturing Process

Before manufacturing first, you have to register with the ROC. Then get Trade License from the Municipality. Also apply for Factory License as per your state rules. Apply for Udyog Aadhar MSME online registration and VAT registration. Get the ‘No Objection Certificate’ from the state pollution control board. Obtain the BIS certification for Quality Control. Open a current bank account in the nationalized bank. Secure your brand by Trademark Registration. And also apply for ISO certification.

Required Machinery for PVC Pipe Manufacturing

- High-speed mixer, nonshell type capacity of 50 kg. per batch/hr with full controls and cooling setup.

- The 65 mm / 18 V PVC rigid pipe extrusion plant consisting of twin-screw extruder, vacuum sizing unit, cooling tank, haul-off unit and cutting machine.

- Dies sizes from 20, 25, 45, 63, 75, 90, 110 mm and mandrel size 2.5 kg/cm2, 4 kg/cm2, 6 kg/cm2 and 10 kg/cm2.

- The scraper, grinder, heavy-duty fitted with Electric Motor.

- Overhead water tank and recycling pump units.

- There is weighing balance, heavy type industrial model with moderate accuracy.

- The pipe storage, racks, maintenance of small hand tools, greasing, oiling equipment etc.

- There is also required for testing laboratory to check chemical balance, oven and other testing equipment. Machine for testing bulk density, specific gravity lead and tin estimation (in ppm).

Raw Materials used for PVC Pipe Manufacturing

The raw materials like PVC resin, DOP, Stabilizers, Processing acids, Lubricants, Colors and Fillers are required for PVC pipe manufacturing. The water and electricity are essential.

PVC Pipe Manufacturing Process

- Extrusion

For PVC pipe manufacturing, PVC uncompounded resin is not suitable for direct process. For smooth process and stability, the additives are required to mix with PVC resin. There are some additives used to manufacturing PVC pipes are: DOP, DIOP, DBP, DOA, DEP.

Plasticizers – there are some common plasticizer used are DOP, DIOP, DOA, DEP, Reoplast, Paraplex etc.

Stabilizers – common stabilizers are lead, barium, cadmium, tin, stearate etc

Lubricants – Buty-Stearate, Glycerol Moni-Stearate, Epoxidised Monoester of oleic acid, stearic acid etc.

Fillers – fillers are used to produce special quality product like calcined clay.

Before process starts the PVC, resin is compounded with plasticizers, stabilizers, lubricants and fillers to improve the process and stability of the product. These ingredients and resin is mixed with the high-speed mixer.

The resin is fed to the double screw extruder and the die and inserts are fitted for required diameter. Next the PVC compounds are passed through heated chamber and melted under the compression of screw and heat of the barrel. The marking is done at the time of extrusion.

Sizing

The pipes come from extruder cooled in sizing operation. There are mainly two types of sizing are used namely Pressure Sizing and Vacuum Sizing.

Traction

After sizing there is traction. The tube traction unit is required for continuous haulage of pipes being extruded by the extruder.

Cutting

The cutting is the last process. There are two types of cutting techniques are used for PVC pipes. Manual and Automatic. In the end the pipes are tested for ISI marks and ready for dispatch.

In India many type of PVC Pipe Manufacturing Machine are make but among this Devikrupa Group Manufactures Best Machines.

Comments are closed.