Groundbreaking studies have led to novel smart window technologies which do not require external electrical energy for their operational needs, hence enhancing their energy efficiency and functionality.

Existing electrochromic smart windows technology requires external power for its operational needs. It is limited to changing colour from transparent to blue and vice versa (switching optical transparency functionality) upon application of an electrical stimulus and blocks both visible and near-infrared radiation, leading to a decrease in the room temperature. Moreover, the cost of electrochromic smart windows is unaffordable to many due to the expensive process and materials involved in it.

Researchers led by Dr. Ashutosh K. Singh at the Centre for Nano and Soft Matter Sciences (CeNS), an autonomous institute under the Department of Science & Technology (DST), Government of India, have addressed this through two studies.

In one of them they have removed the dependency of electrochromic devices on external electrical power for their operational needs. In the second one, they have made the fabrication process more affordable.

The resulting self-powered electrochromic smart window operates through the power stored in its switching operation from transparent to coloured states. This enhances the operational energy efficiency, affordability and energy storage functionality of the new smart windows technology.

The DST is supporting this technology under the “Advanced Materials Technology (AMT)” program for developing Affordable Electrochromic Windows technology in India.

In the first work, the CeNS team has developed a device that can store electrical energy by changing colour upon the application of a small electrical stimulus generated through electrochemical reactions taking place within the device itself resulting from the device configuration. Technically this device is called Redox Potential-Based Self-Powered Electrochromic (RP-SPEC) device and is popularly known as the self-powered smart windows.

In its coloured state, the device blocks both visible and near-infrared (NIR) parts of the electromagnetic spectrum,that significantly leads to a decrease in the room temperature and reducing power consumption.

The device utilizes tungsten oxide (WO3) EC film, vanadium-doped nickel oxide (V-NiO) as the ion storage film, and aluminium as the anode, all coated on a single tin-doped indium oxide (ITO) sheet. This design eliminates the need for an ITO-based counter electrode, making the device cost-effective.

The RP-SPEC smart windows demonstrate a very opaque state and high transmittance modulation of 88% at a 550 nm wavelength. The device retains its switching ability over two thousand cycles and operates by connecting the EC film with an aluminium electrode. During coloring and bleaching, the device generates voltages of 1.1 and 1.2 V, respectively, and 1.7 V between the Al and V-NiO films. The use of Al3+-based electrolytes instead of Li+ further reduces costs. This work, carried out by Dr. Ashutosh K. Singh and his co-workers, was recently published in the journal ‘Small‘.

Figure: Schematic representation of redox potential difference among the materials used in redox potential-based self-powered electrochromic (RP-SPEC) device or “self-powered smart windows” and its operational states

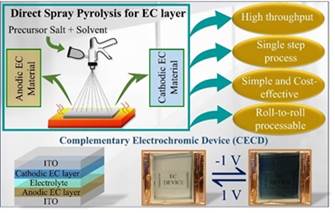

In the second research work Dr. Ashutosh K. Singh’s team developed the fabrication process of electrochromic smart window and made it more affordable by using an industrially adaptable solution-based spray coating approach. Under this process, the affordable electrochromic smart windows technology retained its functionalities, such as the seamlessly switching between coloured and transparent states while possessing energy storage capabilities, that can power the portable device

Existing fabrication processes of electrochromic smart windows involve complicated multi-steps, which result in increasing the product cost. Against these drawbacks, Dr. Singh’s team has developed a single-step direct deposition of electrochromic active materials through spray-coating — a straightforward route to fabricate affordable electrochromic windows. The device employs tungsten oxide (WO3 ) as the cathode and Nickel Oxide (NiO) as the anode, achieving a high level of color contrast.

The 25 cm² large-scale electrochromic smart window device showcases 67% optical contrast at a 550 nm wavelength, with rapid switching times of 10 and 17 seconds. It also achieves a high coloration efficiency of 82 cm²/C (centimetre square/Coulomb) and significant switching capability over 400 cycles. This study was published in the “Journal of Materials Chemistry C”.

Figure: The schematic of spray-pyrolysis to fabricate the cathodic and anodic electrochromic (EC) electrodes, with its advantages over other processes (Top). The schematic with the images of the colored state and transparent state of the electrochromic device (bottom).

“The development of these electrochromic devices represents a major step towards sustainable energy utilization in buildings. By optimizing the process parameters and adopting cost-effective materials, we have created devices that not only enhance energy efficiency but also offer scalable and affordable solutions for modern infrastructures,” Dr. Ashutosh K. Singh pointed out.

Comments are closed.